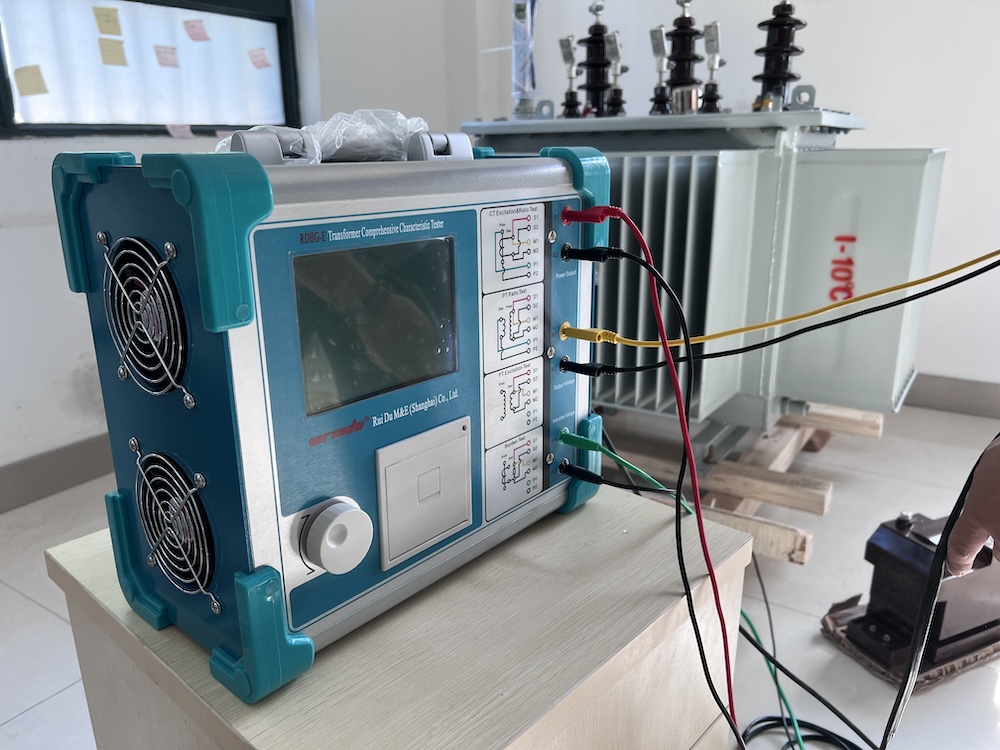

Application of Transformer Comprehensive Testing Instruments

In power systems, transformers play a crucial role in ensuring the accuracy of current and voltage measurements. They convert high voltage and high current into measurable low voltage and low current, providing the foundation for protection, metering, and control. To ensure the performance and reliability of transformers, regular testing and calibration are essential. The transformer comprehensive testing instrument, as a specialized device, can efficiently and accurately conduct comprehensive tests on transformers. This article will delve into the applications, working principles, and significance of transformer comprehensive testing instruments in practical operations.

Functions of Transformer Comprehensive Testing Instruments

1. Performance Testing

Transformer comprehensive testing instruments can perform multiple performance tests on current transformers (CT) and voltage transformers (PT), including:

Voltage-Current Characteristic Testing:

This test applies different levels of current or voltage to measure the response of the transformer and plot the voltage-current characteristic curve. These curves not only help engineers evaluate the transformer's performance under different operating conditions but also reveal potential issues.

Transformation Ratio Measurement:

The testing instrument inputs known current or voltage and measures the output to calculate the transformation ratio. Ensuring that the transformation ratio meets design requirements is crucial because an inaccurate transformation ratio can lead to measurement errors, affecting the entire system's operation.

Polarity Testing:

This test verifies whether the transformer's connections are correct, preventing data collection errors caused by incorrect polarity.

2. Excitation Characteristic Testing

Excitation characteristic testing is an important step in assessing CT and PT performance under different load conditions. By applying different voltages and measuring the corresponding excitation currents, excitation curves can be plotted. These curves help technicians understand whether the transformer will experience saturation under high-load conditions, affecting its measurement accuracy.

3. Secondary Winding Resistance Measurement

Using a four-wire measurement method to accurately measure the resistance of the secondary winding can determine whether the internal connections of the transformer are good. High contact resistance may lead to signal attenuation, affecting data collection accuracy.

4. Data Recording and Analysis

Modern transformer comprehensive testing instruments are typically equipped with data storage and analysis functions that can record multiple test data sets and generate detailed reports. This is crucial for subsequent analysis and troubleshooting. Engineers can use this data for trend analysis, predict potential issues with equipment, and develop corresponding maintenance plans.

Application Areas

1. Power Substations

In substations, regularly using transformer comprehensive testing instruments to test equipment can promptly identify potential issues and ensure safe operation of the power grid. For example, by regularly checking CTs and PTs, protection relays can be ensured to function correctly, thus avoiding large-scale power outages caused by equipment failures.

2. Power Equipment Manufacturing

During manufacturing processes, using these instruments to conduct comprehensive tests on newly produced transformers ensures that their performance meets industry standards. Manufacturers typically implement strict quality control before products leave the factory to guarantee product quality.

3. Research and Education

In universities and research institutions, transformer comprehensive testing instruments are used in teaching experiments and research projects to help students understand transformer operating principles and performance characteristics. For instance, students can learn through hands-on experience how to conduct voltage-current characteristic tests and analyze results, which is crucial for training future engineers.

4. On-Site Maintenance and Repair

These instruments are portable and suitable for on-site use. Technicians can quickly conduct equipment tests to improve work efficiency. During on-site maintenance, technicians can make quick decisions based on real-time data to address equipment failures promptly.

Working Principles

Transformer comprehensive testing instruments typically utilize advanced Digital Signal Processing (DSP) technology to generate required voltage sources through controlled amplifier output modules while collecting data from transformers for analysis. The main components include:

DSP Control Calculation Module:

Responsible for setting test parameters and controlling the entire testing process, including input signal frequency and amplitude.

Amplifier Output Module:

Generates appropriate voltage or current as needed to simulate actual operating conditions.

AD Sampling Module:

Real-time collects output data from transformers through high-speed analog-to-digital conversion to transform analog signals into digital signals for further processing.

Data Processing Module:

Analyzes collected data and generates reports in various formats such as charts or curves, allowing engineers to intuitively understand equipment performance.

Practical Operation Considerations

Correct Wiring:

Ensure all connections are correct to avoid measurement inaccuracies due to wiring errors. Before connecting, carefully check each terminal's labeling and follow the connection diagrams provided in the product manual.

Environmental Conditions:

Conduct tests in stable environments with minimal interference to improve data accuracy. Avoid performing tests in high humidity or high-temperature conditions as these factors may affect equipment performance.

Regular Calibration:

Periodically calibrate the testing instrument to ensure its measurement accuracy meets standard requirements. It is recommended to follow the calibration cycle provided by the manufacturer for regular checks while recording each calibration result for reference.

Training and Skill Enhancement:

Operators should receive professional training to familiarize themselves with equipment operation procedures and safety precautions to ensure safe and effective completion of various testing tasks.

With the development of smart grids, there are increasing demands for transformer performance; thus, transformer comprehensive testing instruments have become essential tools for ensuring safe operation in power systems. By conducting comprehensive and accurate tests on transformers, potential issues can be identified and resolved promptly, laying a foundation for intelligent automation management. In today's increasingly modernized environment, mastering the use of these tools and their application scenarios will help professionals in the electricity industry enhance work efficiency while ensuring equipment safety—providing strong support for the stable operation of the entire power system.