DC leakage and DC withstand voltage test

1.Significance and characteristics of the test

The significance of measuring DC leakage current:

The principle of measuring the DC leakage current of an insulator is basically the same as that of measuring the insulation resistance. The difference is that the voltage of the DC leakage test is generally higher than that of the megohmmeter and can be adjusted arbitrarily. Therefore, it is more effective than the megohmmeter in finding defects, and can sensitively reflect cracks in porcelain insulation, internal moisture and local loose fractures of interlayer insulation, deterioration of insulating oil, carbonization of insulation surface, etc.

Since the voltage values of DC withstand voltage and leakage tests are generally high (2-2.5 times Ue), they are destructive tests.

The significance of DC withstand voltage test:

Although the DC withstand voltage test and the leakage current measurement method are the same, their functions are different. The former is to test the insulation's dielectric strength, and its test voltage is higher; the latter is used to check the insulation condition, and the test voltage is relatively low.

When conducting a DC withstand voltage test, the leakage current reading is usually used to find defects. For example, when the three-phase leakage current is measured to be too different or grows too fast, the test voltage can be increased or the withstand voltage duration can be extended according to the specific situation to find defects.

Therefore, DC withstand voltage is more special for finding certain local defects. It is currently widely used in preventive tests of high-voltage motors, generators, capacitors, lightning arresters, etc.

Compared with the AC withstand voltage test, the DC withstand voltage test has the following characteristics: 1) The test equipment is light and small, 2) It can measure leakage current at the same time, and 3) It causes less damage to insulation.

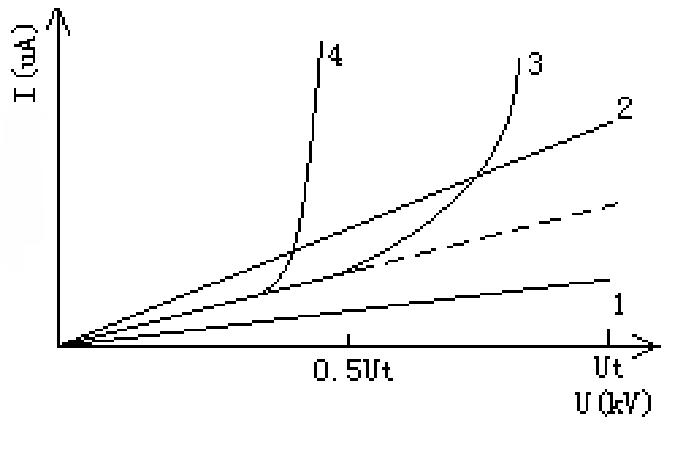

As shown in the following figure: the leakage current of good insulation is shown as curve 1, the insulation affected by moisture is shown as curve 2, and curves 3 and 4 indicate that there are concentrated defects in the insulation. If the leakage current rises rapidly near 0.5Ut, the equipment is in danger of breakdown during operation (excluding overvoltage).

Characteristics of DC withstand voltage test:

DC withstand voltage test has the nature of destructive test to a certain extent. Its disadvantages are: due to the different voltage distribution inside the insulation under AC and DC, and the DC withstand voltage test is not as close to the actual test of insulation as AC.

The equipment required for DC withstand voltage test in the regulations include: metal oxide arrester conductance current measurement (DC 1mA voltage U1mA and leakage current under 0.75 U1mA), generator and motor stator winding, etc.

Why is it not advisable to use DC withstand voltage test for cross-linked polyethylene cables:

1) The electric field distribution of cross-linked polyethylene cable insulation under DC voltage is different from that under AC voltage. Therefore, after the cable that has passed the DC withstand voltage test is put into operation, insulation accidents will also occur under normal working voltage. Such cases have occurred both at home and abroad.

2) DC high voltage test has a cumulative effect on the insulation of cross-linked polyethylene cables. After the cable has passed the DC withstand voltage test, a certain DC residual voltage will remain in the insulation. At this time, putting the cable into use will greatly increase the possibility of breakdown.

3) Applying DC voltage to cross-linked polyethylene cables will accelerate cable aging and shorten service life. During the operation of the cable, the cross-linked polyethylene insulation gradually forms water branches and electrical branches. This process of dendrite formation and aging is accompanied by a rectification effect. Due to the existence of the rectification effect, the charge accumulated at the end of the water branch or electrical branch during the DC withstand voltage test is not easy to dissipate, and the cable dendrite aging process is aggravated during operation.

2. DC withstand voltage test wiring

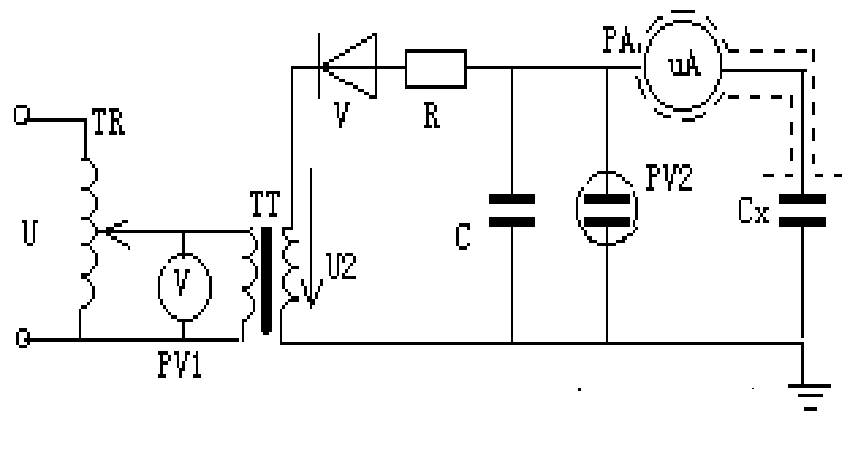

The test principle wiring is as follows, PV2 microampere high voltage electrostatic voltmeter. There are also microampere meters connected to the low voltage side. Since the breakdown field strength is higher under negative polarity voltage in the air, in order to prevent external insulation flashover, negative polarity output is often used in DC tests.

The microammeter is at the high voltage end and is not affected by the stray current from the high voltage to the ground. The leakage current measured is more accurate. However, the microammeter and the leads from the microammeter to the test object should be shielded. Since the microammeter is at high voltage, it is inconvenient to read and switch the range.

DC high voltage power supply: In the simple rectifier circuit mentioned above, the maximum DC output can only be close to the peak voltage of the test transformer. To obtain a higher DC voltage, double voltage rectification is often used to achieve it.

When a higher DC voltage is required and the double voltage circuit cannot meet the requirements, a multi-stage series circuit can be used. A complete set of medium frequency power supply DC generators are generally used on site. The pulsation rate of the DC voltage is generally required to be no more than 2%.

Measurement of DC voltage and leakage current:

At present, high resistance series microammeters are generally used for measurement. When using a DC microammeter to measure the leakage current of the test object, the measurement must be safe and reliable. In addition to protecting the microammeter, the influence of stray (empty leakage) current should also be eliminated. Eliminating stray current is the key to improving test accuracy.

Before the high voltage generator is powered on, it must be grounded. The control box, discharge rod and the equipment under test are all connected to the grounding point of the high voltage generator and then grounded from this point.

RDZG DC high voltage generator adopts PWM high frequency pulse width modulation technology for closed-loop adjustment, with high voltage stability, small pulsation factor and fast and reliable protection circuit.

For detailed product parameters, please click on model RDZG.

For the latest quote, please contact us.

3. DC withstand voltage test precautions

Why does DC withstand voltage use negative polarity?

1. In an extremely non-uniform electric field, the breakdown voltage of the gas has a great relationship with the polarity of the charge carried by the electrode. In the same gap between the rod and the plate, the breakdown voltage of the rod when it is negatively charged is more than twice as high as when it is positively charged. That is, in an uneven electric field, the relationship between the discharge voltage of the gap between the rod and the plate and the polarity of the rod voltage is: the discharge voltage is high when the rod is negative.

The external insulation of electrical equipment is close to this extremely non-uniform electric field. Generally, the external insulation level of electrical equipment is higher than that of the internal insulation, and the defects and faults of the internal insulation are also more than those of the external insulation. When the equipment is subjected to a DC withstand voltage test, although both the internal and external insulation are tested, the main thing is to check the internal insulation. The internal insulation is mainly liquid and solid materials, and inter-electrode shielding measures are adopted. The positive and negative polarity voltages have little effect on the insulation breakdown. For example, the cable insulation is only 10% lower than the negative polarity in the positive polarity breakdown. When applying a DC high-voltage test voltage to the equipment, it is generally not desirable for the external insulation to flash over. For this reason, a negative polarity DC voltage is used.

2. In the DC high voltage test, the insulation of the inspection equipment is mainly based on the moisture and water it contains, which is the key to the insulation quality. Since water has the electrodialysis phenomenon (that is, water molecules have the properties of positive ions in the electric field), during the test, high voltage is applied to the live parts. Since high voltage is negative, water is easily adsorbed near the high voltage electrode, making it easy to detect defects in the object being tested.

Test Notes:

(1) The layout of the test equipment should be safe and easy to operate. There should be a sufficient safety distance from the ground and surrounding equipment, and the grounding wire should be firm and reliable.

(2) The surface of the test product should be wiped clean (or shielded) to eliminate the measurement error caused by the dirt on the surface of the test product.

(3) The test product that can be tested in phase should be tested in phase, and the non-test phase should be short-circuited and grounded.

(4) After the test line is connected, it should be checked by other personnel and the safety fence should be built before the test can be carried out.

(5) The test should be carried out by at least two people, one for supervision and one for operation.

(6) Overvoltage protection should be set before boosting, and the boost speed can be unlimited within 30% of the test voltage. After that, the voltage should be boosted evenly, about 3% of the test voltage per second.

(7) The boost operation can be carried out only after the high-voltage indicator light is on. Before the formal test, boost the voltage at no load to check whether the test equipment is intact.

(8) During the test, the voltage should be kept at a constant value for more than 1 minute during the pressurization process to observe whether the leakage current has a tendency to increase or fluctuate. During the generator test, the voltage should be increased in stages at 0.5 times the rated voltage per stage, and the voltage should be kept at a constant value for 1 minute at each stage. During the cable test, the voltage should be kept at the test voltage for 5 minutes to observe and read the leakage current value.

(9) The principle of selecting the current limiting resistor of the high-voltage circuit: the short-circuit current should be limited to the allowable current of the diode short-circuit, without causing excessive voltage drop, and ensuring the reliable operation of the overcurrent relay. When the test object is broken down, the overcurrent relay should cut off the power supply within 0.02s. Generally, a resistance of 0.5-1MΩ should be selected for every 100kV.

(10) After the test is completed, first disconnect the high-voltage power supply, then disconnect the industrial frequency power supply. Then perform the discharge operation. The test object must be discharged. The discharge personnel must wear insulating gloves, and the grounding lead of the discharge rod should be tilted as far as possible to the rear end.

(11) When measuring the conductance current of a lightning arrester, a current between 950μA and 1050μA can be considered to be 1mA. The measurement error caused by this is very small and fully meets the requirements.

4. Influencing factors and result analysis of the test

Factors that affect the test results are:

1. Leakage current of high-voltage connecting wire to ground (free air around live equipment). Elimination method: minimize the length of high-voltage wire, use insulated high-voltage wire, etc.

2. The influence of air humidity on surface leakage current. Elimination method: If the air humidity is high and the test is forced, you can measure the air leakage first to eliminate the influence. Clean the surface of the equipment, etc.

3. The influence of temperature on the results of high-voltage DC test is extremely significant. The measured current must be converted to the same temperature before analysis and comparison can be carried out. It is best to conduct the test when the temperature of the test object is 30-80℃, because the leakage current changes significantly in this temperature range.

4. Influence of residual charge: In order to eliminate the influence of residual charge, the test object should be fully discharged before the test.