What are the common faults and maintenance methods of vacuum oil filters?

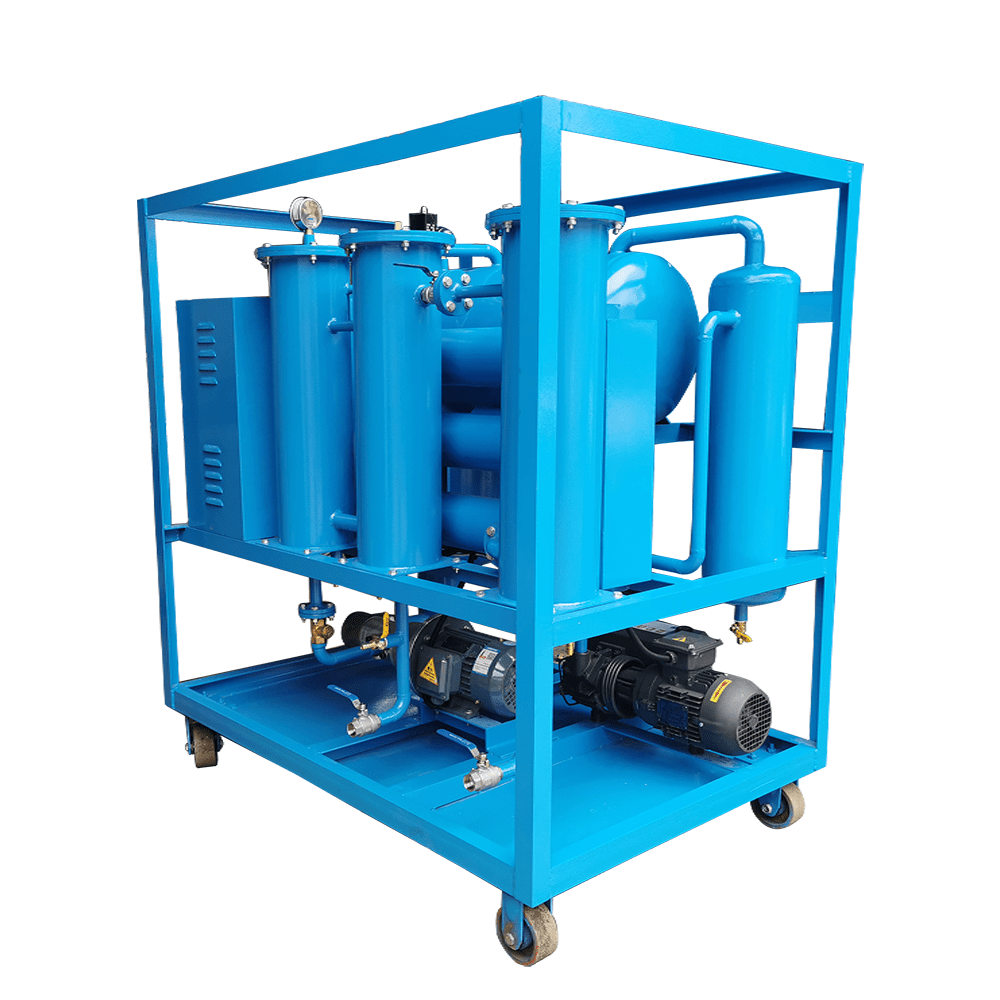

The vacuum oil filter is an equipment that integrates vacuum drying, separation engineering technology, coagulation technology, adsorption technology and precision filtration technology. Under high vacuum conditions, it can quickly and reliably remove moisture, gas, impurities, colloids, sludge and various pigments from oil, reduce dielectric loss and acid value, increase the degree of demulsification, and comprehensively improve the quality of oil.

The vacuum oil filter can meet higher and faster optimization requirements and plays a very important role in purifying the entire oil system. Next, we will introduce the common faults and maintenance methods of the vacuum oil filter:

How to solve the problem that the vacuum degree does not meet the technical standards?

There is too much water in the oil after filtration, and there is too much water vapor in the gas discharged from the vacuum pump. This is a normal phenomenon and requires multiple filtrations;

Because the altitude of the place of use is different, it does not affect the change of vacuum degree under standard atmospheric pressure. Generally, the oil temperature should be increased to allow the water to evaporate;

The vacuum oil level in the vacuum pump is low, so a vacuum pump should be added;

Due to long use time, the vacuum oil needs to be replaced when the moisture content increases;

The seals of each connection are leaking and need to be inspected and repaired;

The consumable parts of the vacuum pump are worn, and the consumable parts should be inspected and replaced.

How to solve the problem of jetting when the vacuum pump is started?

If the vacuum pump seal is displaced or damaged, it should be repaired in time;

The filtered oil contains a lot of water. The oil floats and is sucked into the vacuum pump. The oil level of the vacuum pump rises. The vacuum oil must not be higher than the oil level line.

How to solve poor oil control or no temperature?

The oil temperature is inconsistent with the thermometer, and the oil control needs to be adjusted;

If the heater is burned out, has an open circuit, or has mismatched contact arms, the circuit should be repaired and the heater replaced.

The oil drain pump has no pressure and the oil output is insufficient. How to solve the problem?

If the coarse filter is clogged, the filter should be cleaned in time;

The oil seal of the oil drain pump is leaking, and the oil seal gland needs to be adjusted;

If the oil inlet pipe is blocked, it should be sucked into the bottom of the cylinder and checked in time;

If the oil suction pipe is too thin or the oil suction range is too deep, the environment should be improved in time;

When the oil filling hole of the vacuum cylinder is blocked, it should be cleared in time.

Common maintenance methods

Inspection before starting: Carefully check the oil level of the oil filter vacuum pump and the pollution of the oil to the environment. When the oil is turbid, the dirty oil should be drained from the oil drain valve and clean vacuum pump oil should be injected from the oil filling port of the vacuum pump to raise the oil level to the center line of the oil mark.

After each use of the vacuum oil purifier, if there is oil in the oil collector of the vacuum pump condensation system, or the oil in the vacuum degassing tank overflows into the oil collector, the oil should be drained out in time, and then the oil drain valve should be closed tightly.

When the nozzle of the vacuum degassing tank is clogged, the oil can be drained and compressed with dry air from the inlet of the oil channel, purged or other measures can be taken for transportation.