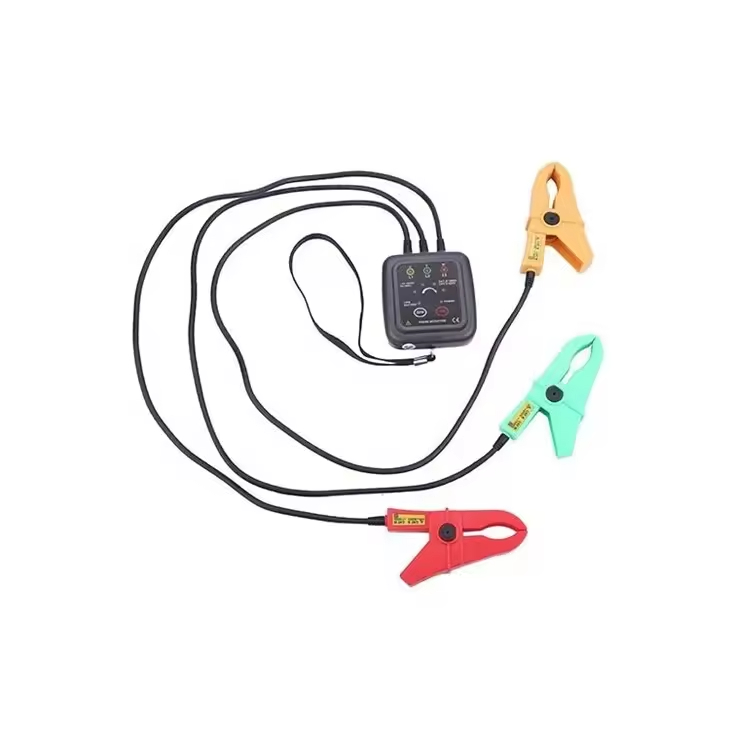

Phase Sequence Tester Phase Detector

- Wrindu

- Shanghai, China

- about 25 days

- 5000 set/month

- RDXZ-2

RDXZ-2 Phase Detector is a major breakthrough in the traditional phase sequence detection method. In the traditional phase sequence detection, the terminal of three-phase wire should be stripped, and the three bare clamps or test pins of the phase sequence meter should be connected to the three bare live wires.

Description

Instead of stripping the wire and contacting the high-voltage bare live wire, the clamp type non-contact inductive measurement is used to directly clamp the three super induction and high insulation clamps to the three bare live wires. At the same time, Phase Sequence Meter indicates the positive or negative phase state of phase sequence of three-phase power supply. There are four powerful magnets on the back of the instrument, which can be hung on the distribution box. At the same time, the Phase Sequence Meter has the functions of live line inspection, simple power inspection, open circuit search, breakpoint positioning, line maintenance and so on. The detection is fast and convenient, and the display is clear at a glance, which greatly improves the safety of the field test, effectively protects the personal safety of the operators, and increases the productivity! Is three-phase power phase sequence, motor detection, line maintenance of the safety instrument

Features

1. The clamp type non-contact inductive measurement is adopted, so that the phase sequence can be detected by directly clamping three super induction high insulation clamps on the insulation skin of three-phase live wire without stripping the cable skin or contacting the high-voltage exposed live wire.

2. Non-contact detection, safe and fast to improve productivity.

3. Dynamic acousto-optic indication of the positive phase or reverse phase state of the three-phase power supply phase sequence is clear at a glance.

4. The bottom plate of the instrument is equipped with four magnets, which can adsorb the instrument on the metal shell of the equipment during the test, so the operation is convenient and handy.

For more power meter testing equipment, please click on Power Meter Testing Solutions

If your company has purchasing needs, please click to contact us, we are always ready to provide you with quotes and solutions.

Specifications

Power supply | 5 batteries (LR6) x2 |

Jaw size | The external diameter of clampable conductor is Φ1.6mm~Φ16mm |

range | AC70~1000V |

Automatic shutdown | It will shut down automatically in about 5 minutes |

work environment | -10 ~ 50 ℃, below 80% RH |

Storage environment | -20 ~ 60 ℃, below 90% RH |

LED display | [positive phase] four phase detection lamps turn on clockwise; |

[reverse phase] four phase detection lamps turn on in turn in a counter clockwise direction; | |

[live electricity] L1, L2 and L3 lights are on within the voltage setting range; | |

[lack of phase] L1 or L2 or L3 lights are not on; | |

[open circuit] L1 or L2 or L3 lights are not on. | |

Beeps | [positive phase] the instrument makes intermittent short sound; |

[reverse phase] the instrument sounds continuously. | |

Battery check | After the power is turned on, the power indicator light is on; when the power is insufficient, the Low Battery light is on |

magnetic force | There are four magnets attached on the back of the instrument, which can be hung on the power distribution box and can withstand the weight of 800g |

Clamp lead length | 0.6m |

maximum voltage | AC1000V |

Insulation strength | 5.4kVrms |

Maximum rated power | 300mVA |

Suitable for safety regulation | En61010-1:2001, en61010-031:2002, pollution level 2, cat Ⅲ (600V), instantaneous overvoltage 6000V |

product quality | About 215g (including battery) |

product size | Width x Height x thickness: 70mm × 75mm × 30mm |