Power cable DC withstand voltage and DC leakage current test

I. Purpose of the experiment

DC withstand voltage mainly test the insulation strength of the cable, is to check the oil and paper cable dry, bubbles, paper insulation in the mechanical damage and process wrapping defects in an effective method, DC leakage current test can be sensitive to reflect the cable insulation moisture and deterioration conditions.

Cable in the role of DC voltage, the voltage in the insulation according to the distribution of resistance, when the cable insulation exists in the development of local defects, the test voltage will be concentrated to the rest of the not yet damaged part, increasing the opportunity to produce electrical breakdown, so that the local insulation defects are more likely to be exposed.

II. Test apparatus

DC High Voltage Generator

RDZG DC high voltage generator adopts PWM high frequency pulse width modulation technology for closed-loop adjustment, with high voltage stability, small pulsation factor and fast and reliable protection circuit. The display adopts green backlight and wide temperature liquid crystal display, which can clearly display data in strong light and dark.

Click RDZG to go directly to the product detail page.

To get the latest quote click on Contact Us.

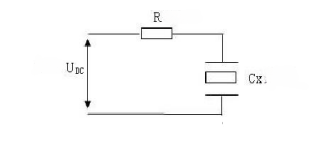

III. Test wiring

IV. Test steps

Ground the cable of the phase under test by fully discharging it, and ground the tester's control box, voltage doubling cylinder, and discharge rod.

Connect the control box to the pressure doubling cylinder with a special cable.

Mount the microamp meter and current limiting resistor on top of the pressure doubling barrel.

One end of the core wire of the cable of the phase under test is led to the tester's microampere meter terminal with a high-voltage shielded wire, and the remaining two phases of the core wire are short-circuited to ground at both ends. And all the cables of the outer sheath short-circuit grounding.

Remove the grounding on the cable core of the phase under test, turn on the power, and close the power knife gate .

Start pressurizing , pressurize to each voltage point to stay 1min, read the current value from the high voltage microammeter, and note down the ammeter reading.

Continuously withstand the voltage at the last test voltage for a total of 15min, time to note down the reading of the ammeter.

If no abnormality occurs within the withstand voltage test, the voltage can be reduced. Press the stop button to cut off the high voltage output when it is reduced to zero. And put the power switch in the off position, and pull the test knife gate.

Discharge with a discharge rod through a resistor first, then short-circuit the high-voltage portion of the booster equipment to ground, and remove the wires after discharging directly to ground.

V. Test criteria

During DC withstand voltage test

The test voltage can be increased uniformly in 4-6 stages, and each stage stays for 1min, and the leakage current value is read. After the test voltage is increased to the specified value, it is maintained for 15min, during which the leakage current at 1min and 15min is read. The influence of stray current should be eliminated during measurement.

Paper-insulated cable leakage current of the three-phase unbalance coefficient (the ratio of the maximum value and the minimum value) should not be greater than 2; when the leakage current of 6/10kV and above cables is less than 20μA, the unbalance coefficient is not specified. Leakage current value and unbalance coefficient is only used as a reference for judging the insulation condition, not as a criterion for whether it can be put into operation. The leakage current value of other cables is not specified.

Cable leakage current with one of the following conditions, the cable insulation may be defective, defective parts should be identified and dealt with:

Leakage current is very unstable;

leakage current rises sharply with the increase of test voltage;

leakage current rises with the prolongation of test time.

VI. Test Precautions

The protective earth and the working earth and the ground wire of the discharge rod should be connected to the ground wire of the test piece separately, and it is forbidden to connect the ground wires in series with each other.

When the following phenomena occur, it means that the specimen has been penetrated, and the pressurization should be stopped immediately and the pressure should be reduced. When the specimen emits loud noise, smoke, gas, arc flash, burning, etc., the ammeter pointer suddenly swings or the meter pointer suddenly rises.

The microammeter is connected to the high voltage side.

Be sure to connect a current limiting resistor.

The voltage is measured directly on the high voltage side by means of a voltage divider.

The specimen should be at a sufficiently safe distance from surrounding objects.

The specimen shall be discharged directly to the ground for more than 5min before the test.