Key Technical Points For Commissioning And Acceptance Of Relay Protection In Smart Substations

As a new model of station construction, smart substations have been put into operation on a large scale like mushrooms after rain, which has had a great impact on many traditional concepts, and corresponding problems have emerged, such as immature technology, lack of training follow-up, lack of management experience, etc. In the main control room, the "analog quantity" in the traditional sense has disappeared; the secondary wiring behind the protection screen has also been replaced by virtual terminals; the five-protection machine familiar to the operating personnel is gone, because the five-protection system is embedded in the background machine.

In addition, smart substations have put forward higher requirements for secondary maintenance personnel, and the commissioning and acceptance of smart stations and the defect detection and processing after commissioning have also become a major problem for relay protection automation professionals. This requires relay protection personnel to have a deep understanding of the differences between smart substations and conventional substations in acceptance.

1. Definition of Smart Substation

Smart substations develop digital programs for secondary systems based on the original traditional technology, and integrate advanced scientific and technological advances such as network communication technology, optoelectronic technology, and information technology to monitor the fully automated operating status. At present, my country's smart substations have undergone comprehensive information reforms under the regulations of relevant departments, which not only changed the original traditional technical operation mode, but also further realized the monitoring, interaction and control of electric energy information, further strengthened the comprehensive use and management of the system, and achieved resource conservation and efficient economic development on the basis of innovation, improved the overall operation rate, and ensured the safety of the operation process.

Smart substations, also known as digital substations, are the development trend of comprehensive automation of power systems and a hot spot in China. Digital substations include all digitalization of information collection, transmission, processing, and output processes of substations. The basic characteristics are intelligent equipment, networked communication, unified models and communication protocols, and automated operation and management. Digital substations cover the entire scope of substations, such as transformers in primary equipment, circuit breakers, transformers, protection, control, and communication in secondary equipment, as well as software development, system modeling, and data application. The construction of digital substations is a systematic project.

It is mainly achieved through the following three aspects.

① In order to avoid electrical connection during the operation of the primary and secondary systems, the photoelectric transformer has better improved its data reception accuracy through digital data collection and the use of intelligent technology;

② The application of CPU mode has promoted the application of hierarchical system hierarchical technology to a certain extent, which can effectively allocate resources and ensure the perfection of the operation of the entire system, so as to process data separately;

③ Communication network information interaction is the main process in the intelligent substation system. It mainly interacts with the received information and the interval layer settings, and transmits internal messages between each layer.

2 Key Points For Commissioning And Acceptance Of Relay Protection In Smart Substations

The commissioning and acceptance process of relay protection devices in smart substations is very different from that in conventional substations. On the one hand, this is mainly because the communication between relay protection devices in smart substations is based on digital signals transmitted over the network, and the original secondary circuit based on point-to-point cable connection is replaced by networked optical cables. Therefore, the debugging tools and methods have undergone qualitative changes. During the debugging of protection devices, the debugging personnel should establish the concept of information flow and clarify the transmission method and direction of various digital information. On the other hand, although the structure and information transmission mode of the relay protection system of smart substations have changed, the functions and operating principles of specific protection devices are basically the same as those of conventional substations. Therefore, during debugging, the debugging personnel will not make much change in the simulation of faults and the judgment basis of the action logic of protection devices.

3. Relay Protection Detection Of Smart Substation

3.1 Detection Of Relay Protection Devices

In order to ensure that the relay protection module can function stably, it must complete strict performance tests before being put into use. Only devices that pass the tests can be installed in the relay protection system. The performance measurement of relay protection equipment should be carried out from two aspects: action effect and response time. Generally speaking, when measuring the above performance, specific current and voltage parameters should be considered. The feedback results of the equipment should be observed in real time during the entire detection process. The system display parameters should be compared and analyzed with the detection equipment to accurately measure the action effect and response time of the relay protection module.

3.2 Inspection Of Generators And Transformers

The performance test of the relay protection module of the smart substation also needs to focus on the generator performance and transformer parameters. The generator performance test should complete the factory inspection and determine whether the voltage index is within the standard range. The transformer test should complete the voltage safety measurement.

4. Analysis Of Relay Protection Debugging Technology For Smart Substations

4.1 Relay Protection Equipment

Before debugging the protection system of the intelligent substation system, maintenance personnel must carry out relevant preparations in combination with the actual situation in order to ensure that the equipment is in good operating condition. After completing the above work, the staff also needs to check the connection of the corresponding pressure plate of the system, check the component parameters of the DC circuit of the power system and other equipment, and after completing the inspection, it is necessary to cut off the power supply and check the various spare parts in the equipment again in order to ensure the normal development of subsequent work. It should be noted that the collected information and data need to be retested, which can not only ensure the accuracy of the data, but also improve the overall work efficiency. In addition, the staff also needs to connect the AC voltage to the intelligent device separately in order to sample and detect the data value, so as to reduce the error of the data itself and ensure the standardization and rationality of the debugging work.

4.2 Channel Debugging

Debugging of relay protection device components The premise of debugging relay protection device components is to ensure the status of each device. Specifically, during the inspection process, attention should be paid to the integrity of the plug-in, avoid loosening of the terminal block and the pressure plate, and ensure that the insulation test of the AC and DC circuits is qualified before debugging. During the inspection of the overall device, it must be carried out in a safe state to ensure the smoothness of the inspection process.

The inspection items include: checking the software version and check code of the relay protection device, checking the switch input and output circuits, checking the zero drift, checking the linearity of current and voltage, checking the alarm function, etc. Especially in the process of checking whether the voltage and current are zero drift values, the terminal block voltage circuit needs to be short-circuited and the corresponding current circuit disconnected before checking. The verification of the accuracy of electrical quantity sampling must ensure that the AC voltage and current are fully connected to the terminal block of the protection device respectively and the detection values are recorded in time. If the instrument is normal, the value detected by the instrument should not have much error with the actual detection value, and the general standard requires it to be within 5%. At the same time, when detecting multiple switching quantities, it is necessary to simulate various system fault conditions and states to ensure the accuracy of the output contact action measurement results during debugging. The protection device electrical quantity and non-electrical quantity protection setting value and function verification and the whole group debugging must be carried out after it has been effectively checked.

In the protection setting value verification process, for overcurrent, quick-break protection setting value verification, differential protection setting value verification, distance protection setting value verification, and zero-sequence voltage and current protection setting value verification, which are all within the scope of setting value verification, it is necessary to check that the setting value report should be completely consistent with the setting value setting notice. It can be seen that the entire process of relay protection element device debugging is relatively complicated, and a complete debugging project guide must be available, and it must be debugged by technicians with corresponding qualifications and experience.

4.3 Debugging Of Monitoring System

The network control system is also the most important part of the development of smart substations, so the performance of network control equipment must be measured. In order to achieve the expected work efficiency, network messages are generally used to support the analysis of the operation results of the equipment. At the same time, message analysis can effectively record the data generated by the operation of the smart substation in real time, and can quickly issue an alarm once an abnormality is detected. The monitoring device applied in the relay protection module can not only effectively measure the working conditions of the substation, but also adjust the operating status of the device. In addition, if the device is abnormal, the cause of the abnormality can be analyzed in real time, laying the foundation for secondary maintenance.

End

Compared with traditional substations, smart substations have added process layer networks and smart electronic devices including merging units and smart terminals, which greatly increases the number of devices faced during relay protection acceptance. At the same time, virtual secondary circuits replace hard-wired circuits such as cables, and rely on communication messages to transmit information, making the interlocking circuits between protection devices more complex. For this reason, the acceptance of relay protection in smart substations focuses on acceptance details, eliminates unsafe factors that affect operation, and lays a solid foundation for the stable operation of the power grid.

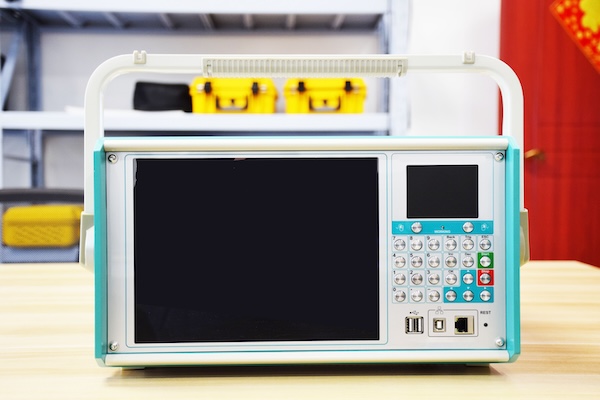

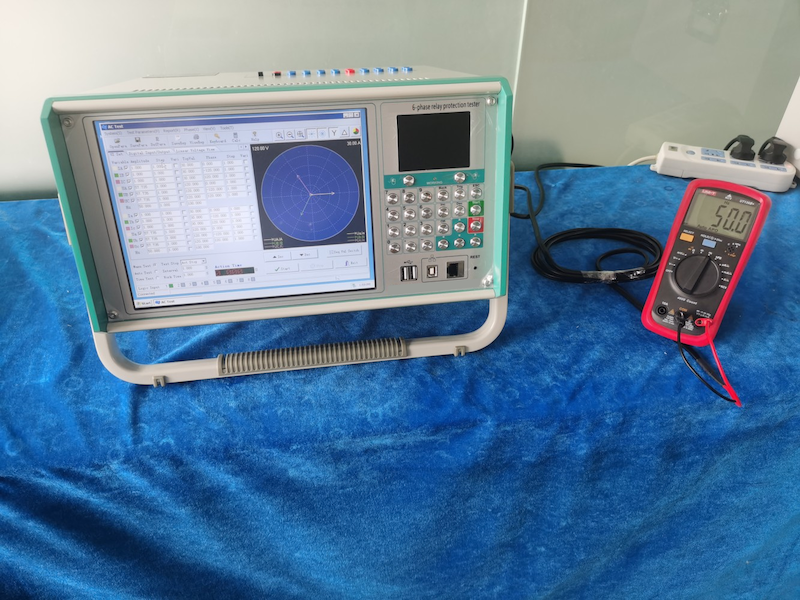

RDJB-1600M Microcomputer Relay Protection Tester is our company extensively listening to user opinions, summarizing the advantages and disadvantages of similar domestic products at present, and fully using modern advanced A new type of miniaturized microcomputer relay protection tester based on microelectronic technology and devices.

For detailed product information and specifications, please click RDJB-1600M.

For the latest quote, please contact us.