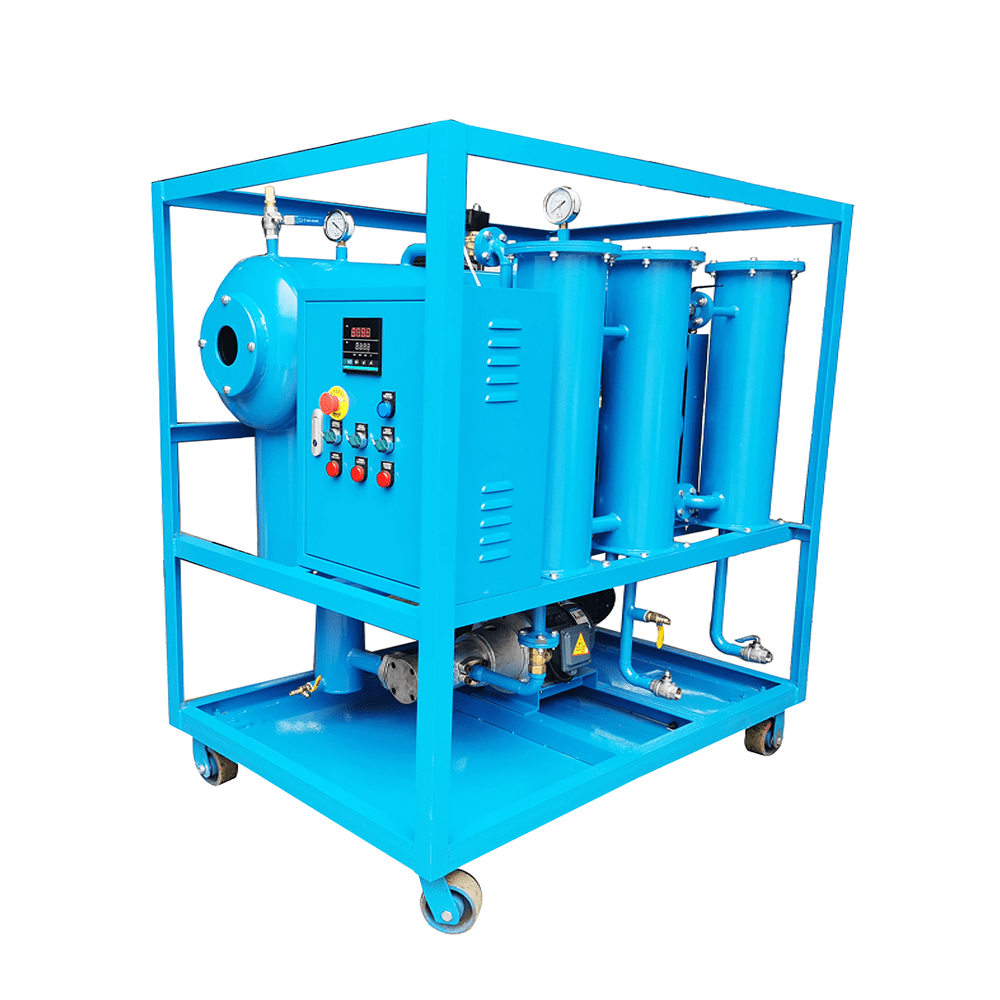

Transformer Oil Purifier In Stock

- Wrindu

- Shanghai, China

- about 25 days

- 5000 set/month

- ZYD

ZYD series Transformer Oil Purifier In Stock feature a T-shaped vacuum chamber for efficient moisture and gas removal, ensuring optimal oil quality for high-voltage applications.

Description

The ZYD series of Transformer Oil Purifier In Stock stands out for its innovative T-shaped horizontal vacuum chamber, which enhances evaporation efficiency and extends machine lifespan. These systems efficiently eliminate trace water, free water, soluble water, dissolved gases, impurities, and fine particles, as well as harmful gases like acetylene, hydrogen, and methane, from both used and new transformer oils.

This results in improved flash point, acidity, interfacial tension, and dielectric strength of the insulating oil. Ideal for purifying a wide range of insulating oils, including transformer oil used in high-voltage transmission and distribution systems, the ZYD series Transformer Oil Purifier In Stock is also suitable for capacitor, mutual inductor, switch, and cable oils.

Main Function

1). Moisture Removal/Dehydration: The treated oil achieves a moisture content of less than 5ppm, ensuring optimal performance and longevity.

2). Gas Removal/Degassing: The oil is degassed to a level of less than ≤0.05%, eliminating dissolved gases that can affect insulation properties.

3). Particle Removal: The final treated oil contains particles of 1 micron or less, reducing the risk of internal contamination and equipment failure.

4). Vacuum Oil Filling/Transferring: This feature enables the safe and efficient transfer of oil into transformers under vacuum conditions.

5). Vacuum Drying Equipment for Transformers: Specifically designed for transformer applications, this equipment facilitates the drying process to ensure the highest quality oil.

6). Vacuum Purification Online Work, Unattended Operation: Under certain conditions, the system can operate autonomously, minimizing human intervention and optimizing efficiency.

Features

1) Unique "T" shape double vacuum separation technology ensures efficient oil treatment.

2)Patented degassing tank with anti-foam structure prevents oil from entering the vacuum pump.

3)Reliable control system with advanced safety features ensures stable long-term operation.

4)Oil atomization process produces particles smaller than 50μm, enhancing efficiency.

5)High density electrical heaters with surface efficiency below 1.5 W/cm2 prevent overheating and oil aging.

6)Liquid level and temperature protectors prevent high temperature and blank heating without oil.

7)Vacuum pump cooler preposition reduces the frequency of changing vacuum pump oil.

8)High precision filter elements prevent particles from re-entering the transformer.

9)Automatic oil discharge pressure protector monitors pressure to protect the machine and operators.

10)High pressure screw type oil pump provides stable oil delivery.

11)Automatic float ball valve and electronic oil level controlling system enable unattended operation.

12)Easy to operate system with troubleshooting tips and reminders for issues.

Parameters

Parameters | Model Unit | ZYD-30 | ZYD-50 | ZYD-100 | ZYD-150 | ZYD-200 | ZYD-250 | ZYD-300 | |

Flow Rate | Liter/hour | 1,800 | 3,000 | 6,000 | 10,000 | 12,000 | 15,000 | 18,000 | |

Recommended Max. oil volume in one storage tank | Tons | 6 | 12 | 24 | 40 | 60 | 90 | 110 | |

Relative Working Vacuum Degree | MPa | -0.08 ~ -0.099 MPa | |||||||

Absolute Operating Vacuum Level | Pa | ≤ 8 Pa | |||||||

Working Discharge Pressure | MPa | ≤ 0.5 | |||||||

Vacuum Pump Capacity | M3/hr | For preliminary rotary vane vacuum pump: 200 m3/hr For booster roots vacuum pump: 1000 m3/hr | |||||||

Temperature Control | ℃ | 0 ~ 100 | |||||||

Operation Oil Temperature in Treatment | ℃ | 30 ~ 80 (65℃ is best) | |||||||

Power Supply |

| AC 3~, 380 V, 50Hz, 4 Wire (or as per your requirements) | |||||||

Operation Mode |

| Continuous Operation | |||||||

Working hours without Trouble | Hour | 4000 | |||||||

Continuous Working Hours | Hour | 150 | |||||||

Ambient Temperature |

| -25 ~ 55℃ | |||||||

Working Noise | dB(A) | 65 ~ 85 | |||||||

Cooling Method |

| Air Cooling | |||||||

Heating Power (adjusted available) | KW | 30 | 72 | 90 | 120 | 135 | 150 | 180 | |

Total Power | KW | 36 | 78 | 105 | 136 | 150 | 170 | 206 | |

Inlet/Outlet | mm | φ25 | Φ32 | φ50 | φ50 | φ50 | φ60 | φ60 | |

Weight | Kg | 500 | 900 | 1200 | 1400 | 1650 | 1800 | 1950 | |

Dimension | Length | mm | 1380 | 1710 | 1800 | 2010 | 2060 | 2100 | 2200 |

Width | mm | 1020 | 1510 | 1560 | 2030 | 2100 | 2150 | 2250 | |

Height | mm | 1760 | 1860 | 2080 | 2080 | 2200 | 2450 | 2550 | |

After Treatment | |||||||||

Dielectric Strength | kV | ≥ 70 ~ 80 | |||||||

Water Content | PPM | ≤ 5 | |||||||

Gas Content | % | ≤ 0.1 | |||||||

Particle Size | μm | ≤ 3 | |||||||

Cleanliness |

| ≤NAS 1638 Grade 5 | |||||||