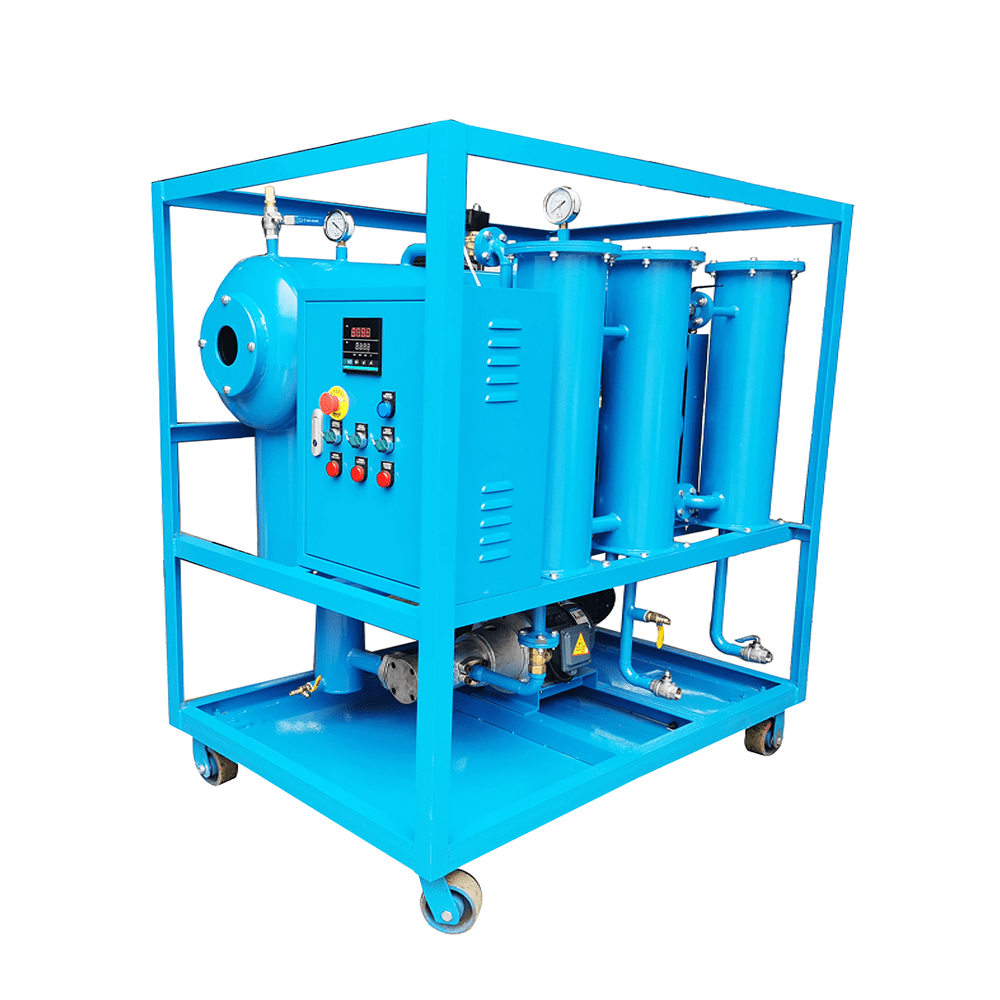

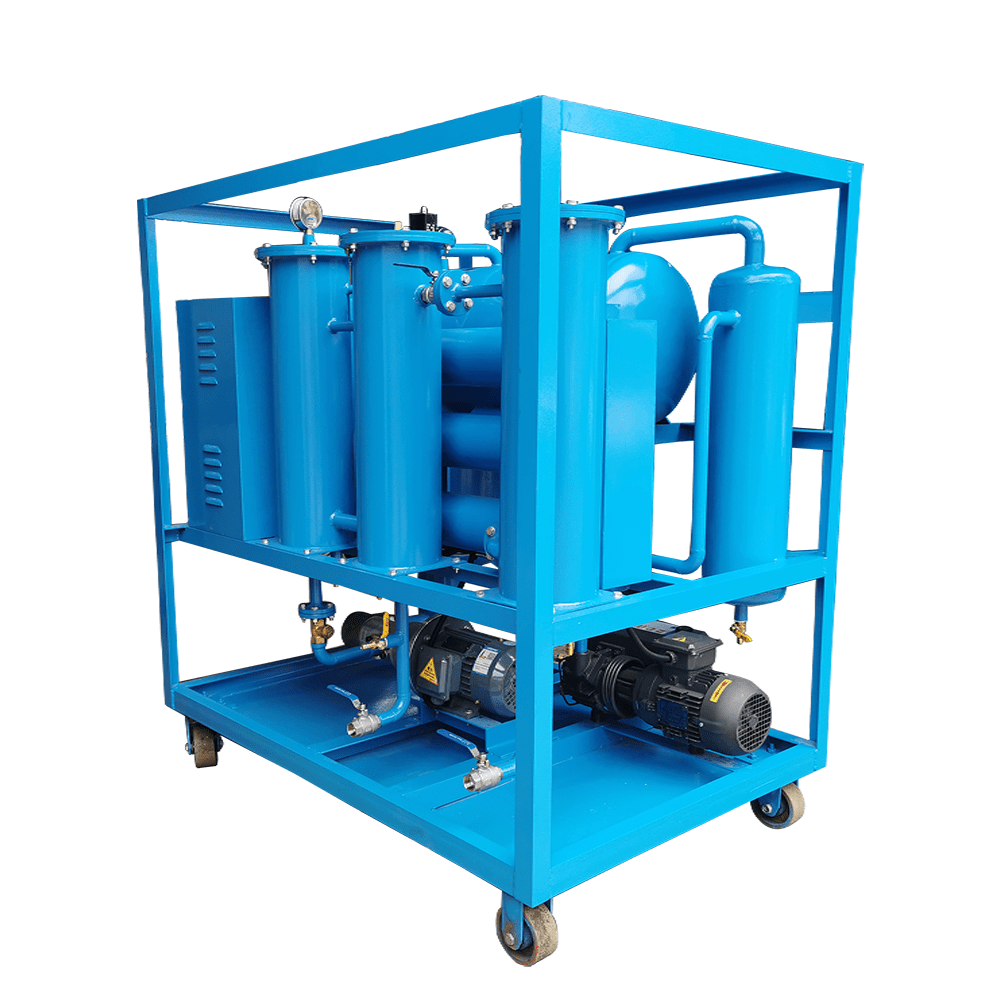

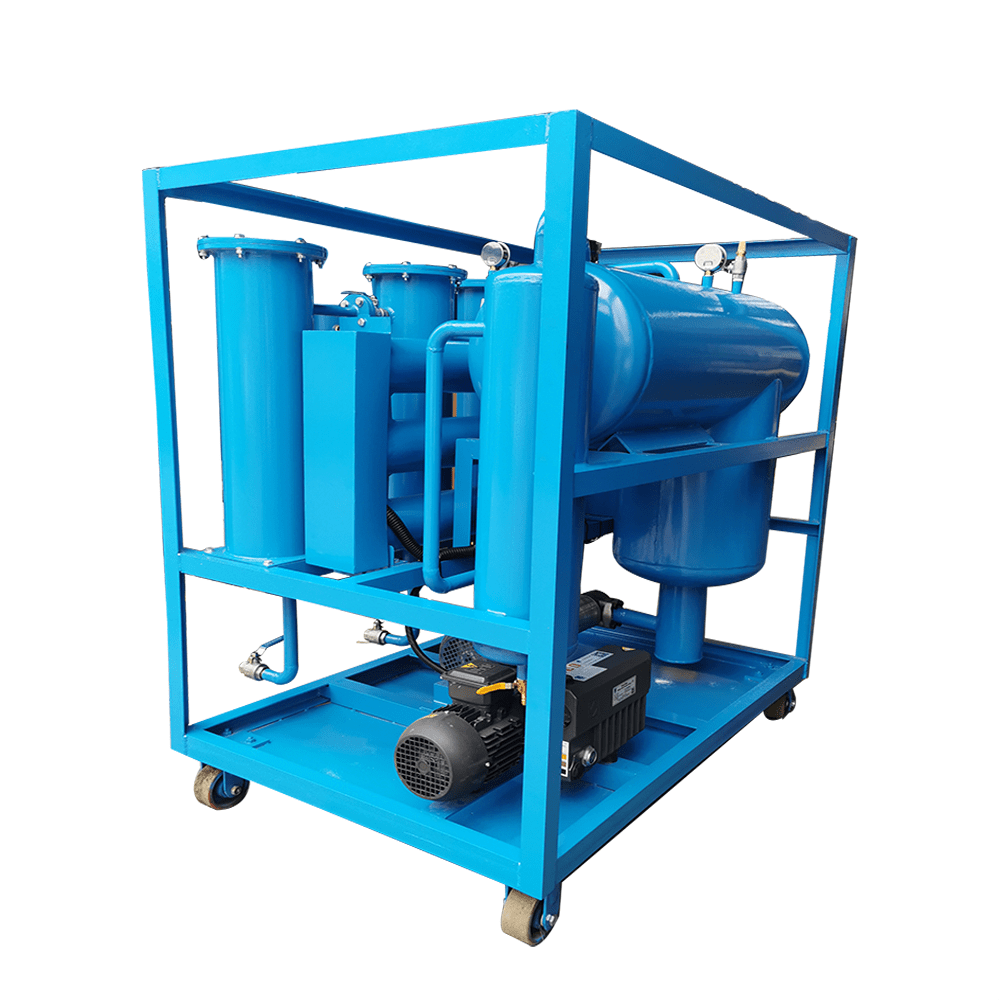

Vacuum Dehydration Oil Purification System

- Wrindu

- ZYA Series

Utilizing cutting-edge vacuum technology and internationally acclaimed stereo-evaporation techniques, this Vacuum Dehydration Oil Purification System achieves unparalleled efficiency in eliminating water, gas, and impurities. Unlike conventional methods requiring power shutdowns or oil changes, transformers can now remain operational while undergoing thorough maintenance.

Description

Utilizing cutting-edge vacuum technology and internationally acclaimed stereo-evaporation techniques, this Vacuum Dehydration Oil Purification System achieves unparalleled efficiency in eliminating water, gas, and impurities. Unlike conventional methods requiring power shutdowns or oil changes, transformers can now remain operational while undergoing thorough maintenance.

This Vacuum Dehydration Oil Purification System is applied by the power station and mine to treat various of unqualified or used insulation oils including aging transformer oil specially for the power below 110kV, mutual inductor oil, switch oil, and so on. Also it can inject the insulating oil into the transformers on-line and dry the transformer.

This type of machine can degas, dewater, removing the impurities of insulating oil quickly and effectively. It improves the value of voltage value, and makes sure electrical equipment work safely.

Features

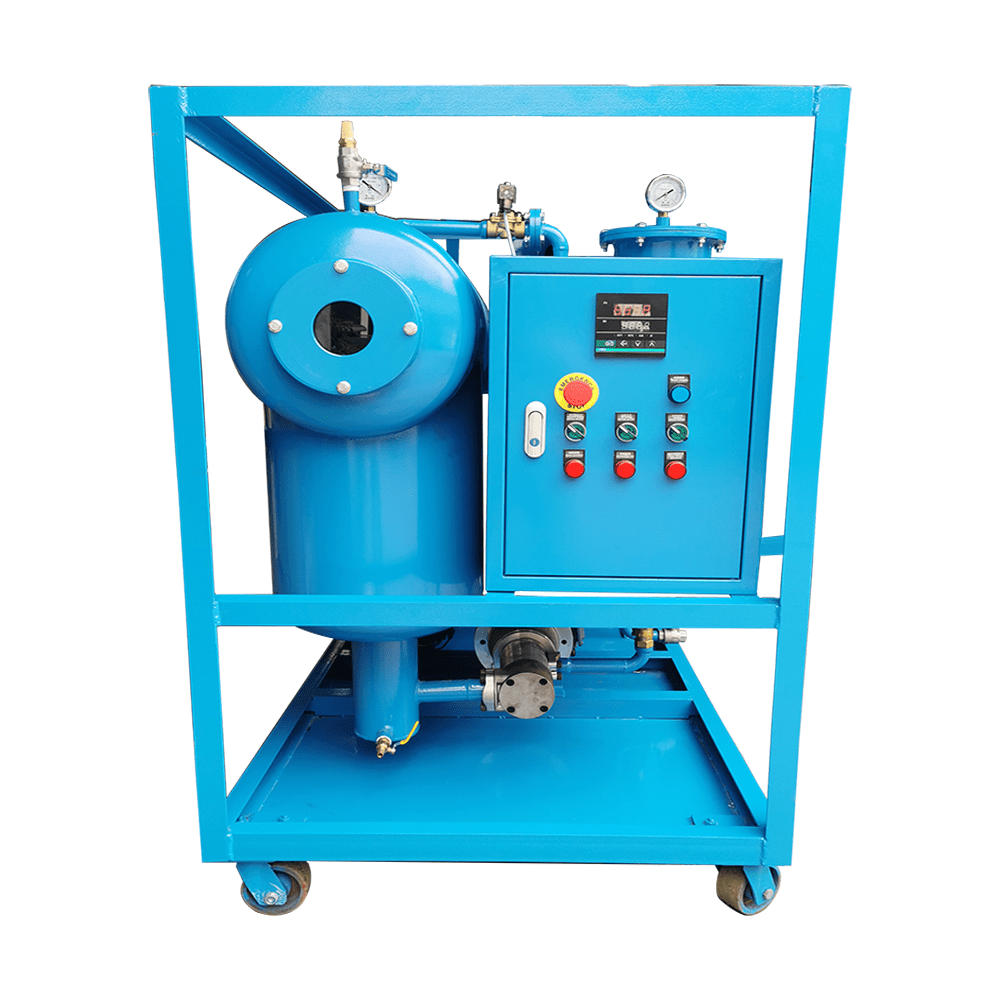

1. This oil filtration unit is compact and highly efficient. It conveniently operates electrical and vacuum oiling for power equipment while effectively removing moisture.

2. Its unique impurity removal technology utilizes double FH trapezoidal network filtering and high polymer absorption, eliminating the need for mechanical power.

3. Utilizing bi-infrared liquid Duplex 3D stereo-evaporation technology, it excels in dewatering and degassing processes, ensuring optimal performance.

4. It can treat oils of any grade on-site and is suitable for heavy-duty, 24-hour continuous operation.

5. Operational flexibility is a key feature. It can function independently or with an optional oil regeneration system.

6. Our oil filtration unit supports both on-load and off-load operation and can be fully automated with a PLC controller option.

7. Advanced dielectric condenser devices ensure reliable performance while reducing maintenance costs and downtime.

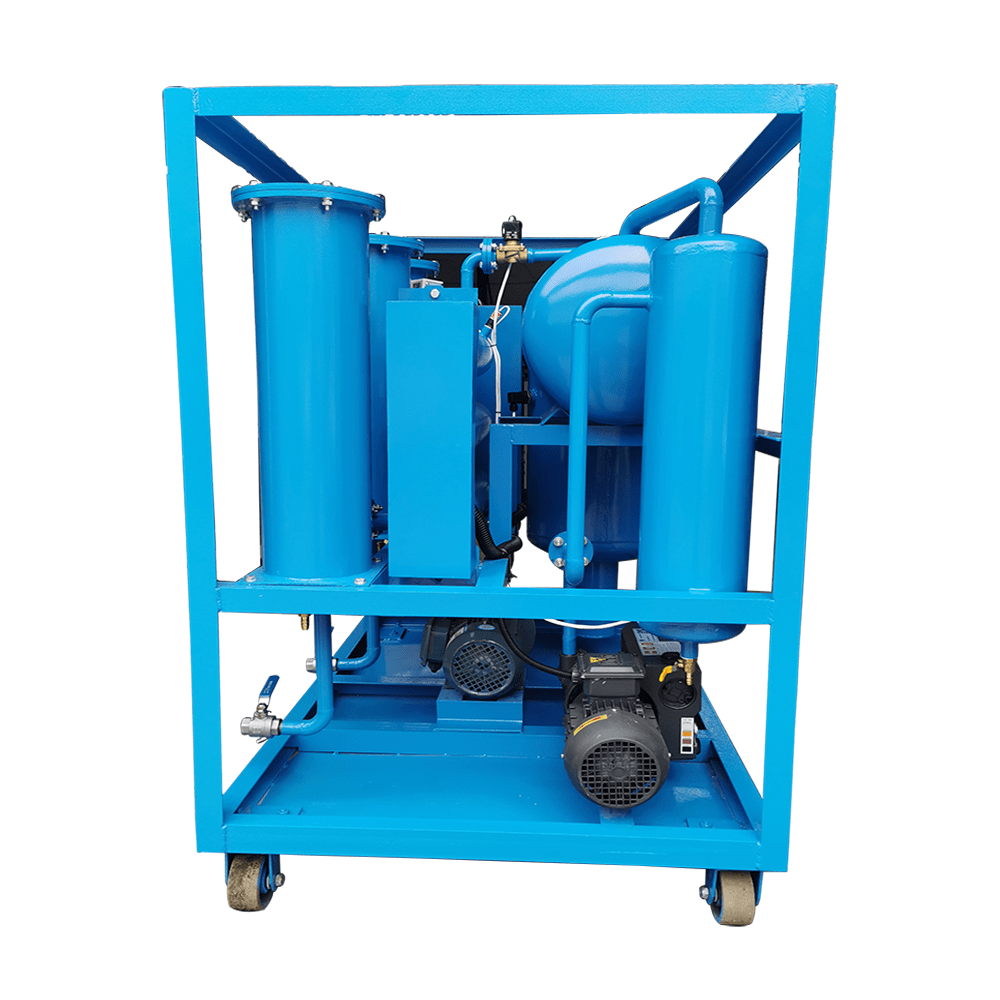

Work Principle

When the oil purifier is activated, the oil is injected into the primary filter through the oil inlet valve. This process effectively removes large impurities, and the heated oil, along with any particles, is directed into the vacuum tank.

Within the vacuum tank, the low pressure and deaeration element work to separate vapor from the oil. The vapor is rapidly vaporized and condensed into water by a cooler or drained away by the vacuum system.

The oil, now free of water, proceeds to the secondary filter and precision filter via an oil pump. Here, all remaining impurities are eliminated, resulting in purified oil as the final product.

Parameter

Parameters | Unit | ZYA-10 | ZYA-20 | ZYA-30 | ZYA-50 | ZYA-100 | ZYA-150 | ZYA-200 | ZYA-300 | |

Flow rate | LPH | 600 | 1200 | 1800 | 3000 | 6000 | 9000 | 12000 | 18000 | |

Working vacuum | MPa | -0.06 ~ -0.095 | ||||||||

Working pressure | MPa | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | |

Working without Trouble | H | 4000 | ||||||||

Continuous Working | H | 150 | ||||||||

Temperature range | ℃ | 20 ~ 80 | ||||||||

Power supply |

| 415V, 3 phase, 50 Hz (or as per your requirements) | ||||||||

Working noise | dB(A) | 61 | 63 | 70 | 70 | 70 | 70 | 70 | 70 | |

Heating power | KW | 8.25 | 14 | 13 | 18 | 24 | 28 | 30 | 48 | |

Total power | KW | 9 | 18 | 16.5 | 20 | 27 | 30 | 37 | 50 | |

Inlet/outlet caliber | mm | φ25 | φ25 | φ25 | φ32 | φ40 | φ50 | φ50 | φ60 | |

Weight | Kg | 150 | 200 | 260 | 300 | 400 | 450 | 550 | 600 | |

Size | L | mm | 1050 | 1050 | 1100 | 1200 | 1450 | 1600 | 1800 | 1900 |

W | mm | 750 | 750 | 800 | 950 | 950 | 1100 | 1200 | 1200 | |

H | mm | 1350 | 1350 | 1400 | 1500 | 1650 | 1800 | 1900 | 1900 | |